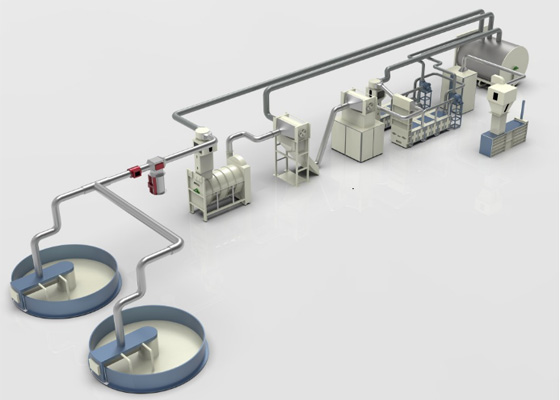

Textile Waste Yarn Recycling Machine Line is suitable for the re-processing of textile waste such as household textiles, waste clothing, yarn, cloth surplus materials, non-woven fabrics. Give the processed textile waste a second life, ecological environmental protection and can maximize the economic benefits for the enterprise. Our textile waste recovery lines feature perfectly matched components and sophisticated mechanical processes. Jinan Morinte Machinery Co., Ltd. has decades of professional textile knowledge, has a wealth of textile waste recycling experience, our production lines in Pakistan, Bangladesh, Egypt and other places have a large number of users, we can assure our customers that we provide the best quality production lines, the most efficient service, the most advanced recycling concept.

According to the needs of different customers, we can be combined with textile waste cutting machine, cotton grab machine, spark metal hawk-eye detector, baler and so on to form a complete production line. Our production line uses the centrifugal force generated by the high-speed rotation of the drum to loosen the textile waste and remove impurities. The fiber produced by our production line has the characteristics of long fiber length, and our production line greatly reduces the damage to the fiber.

Textile Waste Cutting Machine

This series cutting machine is mainly used for cut the waste rags, yarn, clothes, fabric, textiles and chemical fiber, plastic, paper, waste fishing net etc. This equipment with high efficient and east maintenance.

Uses the cutting between the blade roller and fixed blade to cut yarn, fabric etc. into small pieces.

Length is adjustable from 5 cm-20 cm. Speed can be adjustable according to customers' special requirement.

It can meet the requirement of best quality, high output, low cost and also has a feature of reasonable structure, easy operation and the safe production and so on.

Basic Info.

Type | MT800 |

Cutting times | 576/min |

Blade | 4+1 pcs |

Feeding and output conveyor | 1400x350mm |

Power | 5.5 / 7.5kw |

Size | 3200x1100x1000mm |

Eagle Eyes Metal and Spark Diverter

Eagle Eyes Metal and Spark Diverter is the latest product. Lt’s manufactured with high-quality components and materials and incorporates the highspeed microprocessor technology. tis installed on the duct of pneumatic transport systems for materials like fibers or tuft. Lt‘s effectively detects metallic particles and sparks, mixed or generated in the production process. So that ensure the safety of blowing-carding production line in spinning mills or other fiber processing production lines.

Textile Waste Yarn Recycling machine

Textile Waste Yarn Hard waste recycling line include opening machine, cyclon feeding box, recycling machine, auto horizontal baling machine and dust filter.

This line mainly used to process the textile waste, such as knitting and woven fabric waste, yarn waste, nonwoven waste, denim waste, waste garment, banian, waste carpet etc. into fiber, the fiber can be used for yarn making, capacity 200-250kg/hr.

According to different material, there need different qty rollers to be processed, this line designed three output part at 6th, 8th and 10th roller, customers can adjust output position as request, it’s easy operate.

Why Choose us:

1, we have rich production experience. In China, we have our own factory, with workers with rich production experience, our research and development team with high education and high innovation ability, our management team is highly responsible, and our production line is constantly reformed and innovated under the close cooperation of the three parties.

2. Our managers and engineers often participate in exhibitions at home and abroad. At the exhibition, we actively understand the change and innovation of the textile recycling industry, and we learn from the excellent experience at home and abroad that our products have been at the forefront of the industry.

3, we have a large number of end users in foreign countries, and maintain good cooperative relations. With the help of end users, our production line is becoming more and more perfect.

4, we can provide customers with more superior after-sales service, we have their own installation and maintenance team in Pakistan, Bangladesh. A phone call can come to you and save your valuable production costs. In the future, we will set up our own team in more countries.

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.