2025/11/13

Against the backdrop of the global textile industry facing dual challenges of resource consumption and waste disposal, three textile waste recycling devices launched by Jinan Morinte Machinery Co., Ltd. — PCW&PIW Recycling Plant, Textile Waste Recycling Machine, and IRW Recycling Plant — have provided a new solution for the efficient recycling of textile waste, attracting widespread attention from the industry.

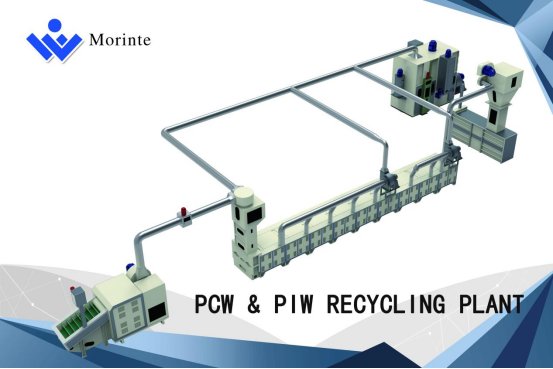

PCW&PIW Recycling Plant: "Fiber Rebirth Technique" for Hard Waste

Aiming at textile "hard waste" such as knitting and woven fabric waste, yarn waste, nonwoven waste, denim waste, waste garment, waste carpet, etc., the PCW&PIW Recycling Plant has built a complete processing system. The production line integrates opening machine, cyclon feeding box, recycling machine, auto horizontal baling machine and dust filter, which can efficiently convert various hard wastes into fibers that can be reused in yarn making, with a processing capacity of 200-250kg/hr.

More innovatively, the production line is designed with three output parts at the 6th, 8th and 10th roller according to the characteristics of different materials. Customers can flexibly adjust the output position according to their needs, greatly improving the convenience of operation. This design not only ensures the adaptability to a variety of wastes, but also provides the possibility of personalized production for enterprises, helping textile enterprises achieve dual benefits of cost reduction and efficiency increase and environmental protection value in the waste disposal link.

Textile Waste Recycling Machine: "All-round Player" in Multi-material Recycling

The new Textile Waste Recycling Machine is widely favored in domestic and foreign markets with its comprehensive advanced technology. It is suitable for processing various yarns and fabric wastes below 40s, such as cotton, polyester, PC, etc. It can also process special materials such as chemical fiber, glass fiber, jute, hump, flax, ramie, as well as yarn waste, hard waste, leftover clothes, denim, polyester waste, non-woven, etc.

The equipment series includes three models: MKS600, MKS400 and MSL250, with processing capacities ranging from 200kg/hr to 350kg/hr. Parameters such as roller size, power and weight also differ according to the models, meeting the production needs of enterprises of different scales. Its reasonable structural design ensures stable operation of the equipment, and it is easy to operate and maintain, safe and reliable. It can be widely used in cotton spinning, toys, clothing, footwear, knitwear and other industries, injecting power into the green cycle of the entire industrial chain.

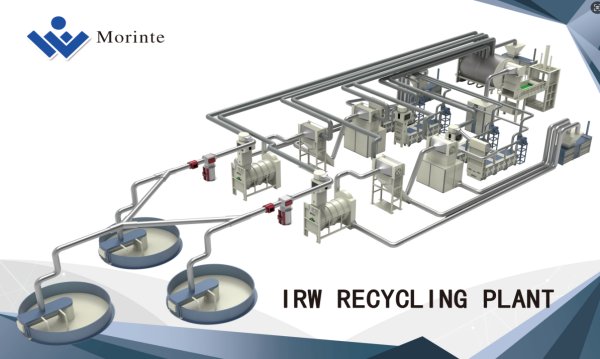

IRW Recycling Plant: "Precision Cleaner" for Soft Cotton Recycling

The IRW Recycling Plant, specially designed for recycling and cleaning soft cotton from spinning mills, can efficiently remove dust and metal impurities from materials such as sweeping, comber noil, linter, cotton dropping, card fly, etc.

The production line adopts the process of "bale plucker feeding — detection by metal and spark detector — three sections cleaning machine + one section carding machine to remove dust and micro dust — auto baling machine for pressing", with an overall processing capacity of 600kg/hr. At the same time, an auto dust baling machine can be equipped as required to collect dust generated by the cleaning machine, further improving the refinement of recycling. The launch of this equipment fills the technical gap in efficient cleaning and recycling of soft cotton textile waste, providing a professional solution for spinning enterprises to realize the recycling of internal waste.

These three devices from Jinan Morinte Machinery cover all scenarios of textile waste disposal from hard waste to multi-material waste and then to soft cotton. At a critical period when the global textile industry is transforming towards green and sustainable development, these devices not only solve the waste disposal problems for enterprises, but also promote the recycling of textile fiber resources, contributing the power of "Made in China" to the low-carbon development of the industry. In the future, with the further enhancement of environmental awareness of textile enterprises, such innovative recycling devices are expected to usher in a broader development space in the global market.

Jinan Morinte Machinery Co.,Ltd.

Tel: 0086-13869178806

Email: samyou@morinte.com; morinte@morinte.com

Website: http://textilefibermachinery.com/; www.cottonwasterecycling.com;