The fiber cutting machine is a versatile cutting equipment with a wide range of applications, covering multiple industries and various material types. For instance, in the textile industry, it can be used to process waste fabric scraps, old clothing, cotton fibers, chemical fibers, linen, textile waste fibers, etc.; in the chemical field, it can cut and process high-strength fibers such as glass fibers and aramid fibers; in the paper industry, it is also used to handle fiber-based raw materials. We are a manufacturer specializing in the production of textile waste cutting machines. We have different models to meet different capacity requirements. We will recommend the appropriate model based on your requirements.

About us

Our Jinan Morinte Machinery Co., Ltd. has been engaged in the production and research of textile waste recycling machinery. Our developed products mainly include textile waste recycling machine production lines, fiber cutting machines, textile waste packaging machines, fiber unpacking machines, and textile waste cleaning machines. After the continuous efforts of our company's R&D team for 15 years, the textile waste recycling equipment produced by our company has been exported to all over the world and has become a powerful textile waste recycling machinery manufacturer in China.

Application of Fiber Cutting Machine

1. Waste fibers and products: It can break down and cut waste fabrics, old clothes, cotton fibers, etc., to achieve the recycling and reuse of resources. For example, after cutting them into short fibers, they can be reused in the production of new products. ,

2. Various chemical fibers: Suitable for sheeting, nylon, acrylic, and vinylon fibers. It can meet the requirements of different specifications and cutting needs.

3. High-strength filament fibers: The specialized high-strength filament fiber cutting machine can precisely cut continuous high-strength, long filament fibers, ensuring that the fibers are not damaged during the cutting process.

4. Other soft materials: Such as leather, cardboard, plastic films, etc. The fiber cutting machine can also effectively cut and shred these soft materials.

Parameters

Model | 800MT | 1200MT | 1600MT | 2400MT |

Capacity | 500–800 kg/h | 800–1200 kg/h | 1000–3000 kg/h | 3000–4000 kg/h |

Main motor | 8P+7.5KW | 8P + 15 kW | 8P + 18.5 kW | 8P + 15 kW(Two sets) |

Conveyer motor | 4p1.5kw | 4p2.2kw(variable frequency motor) | 4p3.0kw(variable frequency motor) | 14p4.0kw(variable frequency motor) |

Belt wheel | Θ100 | Θ140 | Θ120 | Θ140 |

Moving blade base | Θ300 | Θ400*600 | Θ500*800 | Θ600*1200 |

Feeding conveyor | 1400*330 mm | 3000*520 mm | 3000*720 mm | 3000*1100 mm |

Machine size | 2100*1000*1100 | 1400*1450*1500 | 1550*1700*1550 | 2100*1900*1550 |

Cutting size | 2.5.8cm | tunable | tunable | tunable |

Why choose us

1, we have rich production experience. In China, we have our own factory, with workers with rich production experience, our research and development team with high education and high innovation ability, our management team is highly responsible, and our production line is constantly reformed and innovated under the close cooperation of the three parties.

2. Our managers and engineers often participate in exhibitions at home and abroad. At the exhibition, we actively understand the change and innovation of the textile recycling industry, and we learn from the excellent experience at home and abroad that our products have been at the forefront of the industry.

3, we have a large number of end users in foreign countries, and maintain good cooperative relations. With the help of end users, our production line is becoming more and more perfect.

4, we can provide customers with more superior after-sales service, we have their own installation and maintenance team in Pakistan, Bangladesh. A phone call can come to you and save your valuable production costs. In the future, we will set up our own team in more countries

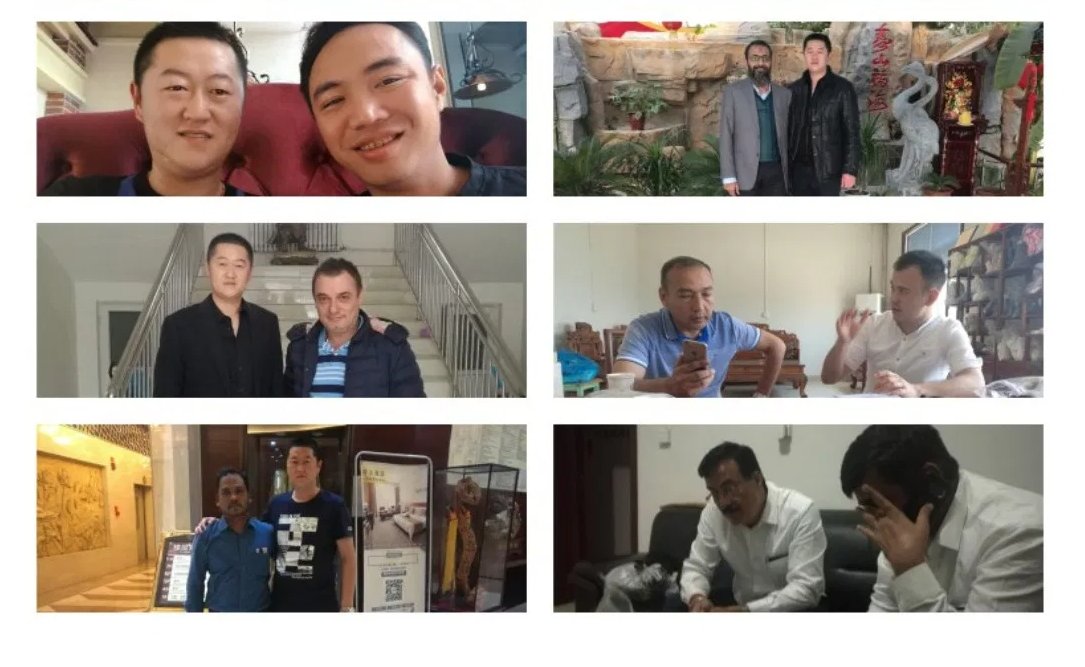

Our customers

Through continuous operational practice and exploration, we have accumulated rich technical experience in the recycling production line of waste spun fibers. We know that not only should we meet the customers' demands, but also provide them with customized solutions and better after-sales services. Only in this way can the customers feel our dedication and sincerity.

After our Morinte people have continuously reformed and innovated over the years, we have developed a unique technical route of our own. Over the years, the countless customers we have accumulated, with the help of customers, have made our product production lines increasingly complete. We have also established good cooperative relationships with customers.

We have our own technical teams in many countries. Whether it is installation or after-sales debugging, we can arrive at the customers' side immediately because we know the importance of time for the customers.Our Jinan Morinte is looking forward to cooperating with more customers. Let's work together to contribute to our global environmental governance and restore our planet to a green land!

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.